Stainless steel plate is generally the floorboard including stainless steel plate and acid-resistant steel plate. Stainless steel plate is a kind of plate to resist weak media like air, steam and water corrosion; while acid resistant steel plate is a type of plate to resist chemical etching mediator referred to acid, alkali, salt etc. corrosion. Stainless steel plate has been a long history since it appeared this century. The invention of stainless steel plate is a major achievement in the world’s metallurgy history. The stainless steel plate establishes important material and technology bases for the development of modern industry and science and technology progress. Choosing good stainless steel plate manufacturers help you reduce quality and economic losses. Ourway steel is your ideal choice about the stainless steel.

Stainless Steel Plate 304

Stainless steel plate has many different varieties and performance. And it has formed a few broad categories in the developing gradually. According to structure organization, it is divided into martensite stainless steel plate (including precipitation hardening stainless steel plate), ferritic stainless steel plate, austenitic stainless steel plate and austenitic with ferritic stainless steel plate; According to main chemical composition or some characteristic elements of steel plate, it also can be divided into chromium stainless steel plate, chromium nickel stainless steel plate, low carbon stainless steel plate, high molybdenum stainless steel plate and high purity stainless steel plate; According to features and applications, it also can be divided into nitric acid resistant stainless steel plate, sulfuric acid resistant stainless steel plate, pitting corrosion resistant stainless steel plate and high strength stainless steel plate etc. According to functional characteristic, it also can be low temperature stainless steel plate, non-magnetic stainless steel plate, free cutting stainless steel plate and super plastic stainless steel plate etc. While the common classification methods are the structural features and chemical compositions. According to processing technology, it is divided into hot rolling and cold rolling including thin cold plate of thickness 0.02-4 mm and middle plate of thickness 4.5-100 mm. According to the characteristics of steel grade, it is divided into five types including austenite, ferrite-austenite, ferrite, martensite and precipitation hardening.

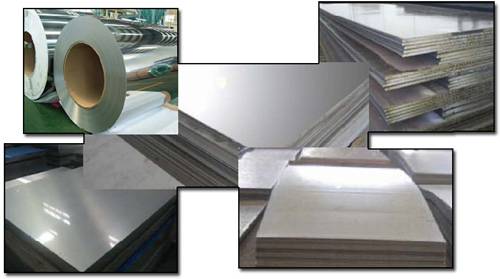

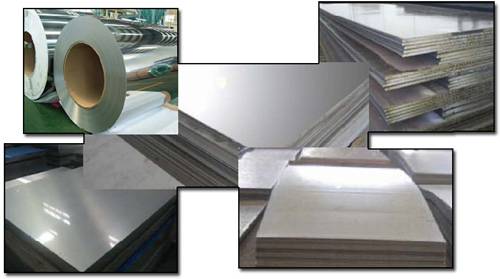

Different Kinds of Stainless Steel Plate

In order to guarantee all kinds of stainless steel to meet requirements in yield strength, tensile strength, elongation, hardness and other mechanical properties, the steel plate must be annealing, solid solution, and aging etc. heat treatment with 05.10 88.57.29.38 special symbols.

Table 1 Domestic Stainless Steel Standard Grade

Stainless Steel Plate 304

Stainless steel plate has many different varieties and performance. And it has formed a few broad categories in the developing gradually. According to structure organization, it is divided into martensite stainless steel plate (including precipitation hardening stainless steel plate), ferritic stainless steel plate, austenitic stainless steel plate and austenitic with ferritic stainless steel plate; According to main chemical composition or some characteristic elements of steel plate, it also can be divided into chromium stainless steel plate, chromium nickel stainless steel plate, low carbon stainless steel plate, high molybdenum stainless steel plate and high purity stainless steel plate; According to features and applications, it also can be divided into nitric acid resistant stainless steel plate, sulfuric acid resistant stainless steel plate, pitting corrosion resistant stainless steel plate and high strength stainless steel plate etc. According to functional characteristic, it also can be low temperature stainless steel plate, non-magnetic stainless steel plate, free cutting stainless steel plate and super plastic stainless steel plate etc. While the common classification methods are the structural features and chemical compositions. According to processing technology, it is divided into hot rolling and cold rolling including thin cold plate of thickness 0.02-4 mm and middle plate of thickness 4.5-100 mm. According to the characteristics of steel grade, it is divided into five types including austenite, ferrite-austenite, ferrite, martensite and precipitation hardening.

Different Kinds of Stainless Steel Plate

In order to guarantee all kinds of stainless steel to meet requirements in yield strength, tensile strength, elongation, hardness and other mechanical properties, the steel plate must be annealing, solid solution, and aging etc. heat treatment with 05.10 88.57.29.38 special symbols.

Table 1 Domestic Stainless Steel Standard Grade

| China | Japan | U.S.A | U.K. | Germany | France | Russia |

|

GB1220-92 GB3280-92 |

JIS | AISIUNS | BS970BS1449 |

DIN17440 DIN17224 |

NFA35-575 NFA35-576 |

ГОСТ5632 |

| 0Cr13 | SUS410S | S410 | ||||

| 1Cr13 | SUS410 | 410 | 410S21 | X7Cr13 | Z6C13 | 08X13 |

| 2Cr13 | SUS420J1 | 420J1 | 420S29 | X20Cr13 | Z20C13 | 20x13 |

| 1Cr17 | SUS430 | 430 | ||||

| 7Cr17 | SUS440A | 440A | ||||

| 9Cr18 | SUS440C | 440C | X105CrMo17 | Z100CD17 | 95X18 | |

| 0Cr18Ni9 | SUS304 | 304 | 304S15 | X5CrNi189 | Z6CN18.09 | 08X18H10 |

| 00Cr19Ni10 | SUS304L | 304L | 304S12 | X2CrNi189 | Z2CN18.09 | 03X18H11 |

| 0Cr17Ni12Mo2 | SUS316 | 316 | 316S16 | X5CrNiMo1812 | Z6CND17.12 | |

| 00Cr17Ni14Mo2 | SUS316L | 316L | 316S12 | X2CrNiMo1812 | Z2CND17.12 | 03X17H14M2 |

| 0Cr18Ni11Ti | SUS321 | 321 | X10CrNiTi189 | Z6CNT18.10 | 08X18H10T | |

| 0Cr18Ni11Nb | SUS347 | 347 | 347S17 | X10CrNiNb189 | Z6CNNb18.10 | 08X18H12F |

Table 2 Chemical Compositions of Martensite, Ferrite, Austenite and Diphasic Stainless Steel

| Grade | Mark | Chemical Compositions(%) | ||||||||||

| C | Cr | Ni | Mn | P | S | Mo | Si | Cu | N | Others | ||

| 201 |

1Cr17Mn 6Ni5N |

≤0.15 |

16.00- 18.00 |

3.50- 5.50 |

5.50- 7.50 |

≤0.060 | ≤0.03 | - | ≤1.00 | - | ≤0.25 | - |

| 201L |

03Cr17Mn 6Ni5N |

≤0.03 |

16.00- 18.00 |

3.50- 5.50 |

5.50- 7.50 |

≤0.060 | ≤0.03 | ≤1.00 | ≤0.25 | |||

| 202 |

1Cr18Mn 8Ni5N |

≤0.15 |

17.00- 19.00 |

4.00- 6.00 |

7.50- 10.00 |

≤0.060 | ≤0.03 | ≤1.00 | - | ≤0.25 | - | |

| 204 |

03Cr16Mn 8Ni2N |

≤0.03 |

15.00- 17.00 |

1.50- 3.50 |

7.00- 9.00 |

0.15- 0.30 |

||||||

| China |

1Cr18Mn10Ni 5Mo3N |

≤0.10 |

17.00- 19.00 |

4.00- 6.00 |

8.50- 12.00 |

2.8- 3.5 |

0.20- 0.30 |

|||||

| Russia |

2Cr13Mn 9Ni4 |

0.15- 0.25 |

12.00- 14.00 |

3.70- 5.00 |

8.00- 10.00 |

|||||||

| China |

2Cr15Mn 15Ni2N |

0.15- 0.25 |

14.00- 16.00 |

1.50- 3.00 |

14.00- 16.00 |

0.15- 0.30 |

||||||

|

1Cr18Mn 10Ni5Mo3N |

≤0.15 |

17.00- 19.00 |

4.00- 6.00 |

8.50- 12.00 |

≤0.060 | ≤0.03 |

2.8- 3.5 |

≤1.00 | - |

0.20- 0.30 |

- | |

| 301 | 1Cr17Ni7 | ≤0.15 |

16.00- 18.00 |

6.00- 8.00 |

≤2.00 | ≤0.065 | ≤0.03 | - | ≤1.00 | - | - | - |

| 302 | 1Cr18Ni9 | ≤0.15 |

17.00- 19.00 |

8.00- 10.00 |

≤2.00 | ≤0.035 | ≤0.03 | - | ≤1.00 | - | - | - |

| 303 | Y1Cr18Ni9 | ≤0.15 |

17.00- 19.00 |

8.00- 10.00 |

≤2.00 | ≤0.20 | ≤0.03 | 1) | ≤1.00 | - | - | - |

| 303se |

Y1Cr18Ni 9Se |

≤0.15 |

17.00- 19.00 |

8.00- 10.00 |

≤2.00 | ≤0.20 | ≤0.03 | - | ≤1.00 | - | - | Se≥0.15 |

| 304 | 0Cr18Ni9 | ≤0.07 |

17.00- 19.00 |

8.00- 10.00 |

≤2.00 | ≤0.035 | ≤0.03 | - | ≤1.00 | - | - | - |

| 304L | 00Cr19Ni10 | ≤0.03 |

18.00- 20.00 |

8.00- 10.00 |

≤2.00 | ≤0.035 | ≤0.03 | - | ≤1.00 | - | - | - |

| 304N1 | 0Cr19Ni9N | ≤0.08 |

18.00- 20.00 |

7.00- 10.50 |

≤2.00 | ≤0.035 | ≤0.03 | - | ≤1.00 | - |

0.10- 0.25 |

- |

| 304N2 |

0Cr18Ni 10NbN |

≤0.08 |

18.00- 20.00 |

7.00- 10.50 |

≤2.00 | ≤0.035 | ≤0.03 | - | ≤1.00 | - |

0.15- 0.30 |

Nb≤0.15 |

| 304LN |

00Cr18Ni 10N |

≤0.03 |

17.00- 19.00 |

8.50- 11.50 |

≤2.00 | ≤0.035 | ≤0.03 | - | ≤1.00 | - |

0.12- 0.22 |

- |

| 305 | 1Cr18Ni12 | ≤0.12 |

17.00- 19.00 |

10.50- 13.00 |

≤2.00 | ≤0.035 | ≤0.03 | - | ≤1.00 | - | - | |

| 309S | 0Cr23Ni13 | ≤0.08 |

22.00- 24.00 |

12.00- 15.00 |

≤2.00 | ≤0.035 | ≤0.03 | - | ≤1.00 | - | - | |

| 310S | 0Cr25Ni20 | ≤0.08 |

24.00- 26.00 |

19.00- 22.00 |

≤2.00 | ≤0.035 | ≤0.03 | - | ≤1.00 | - | - | - |

| 316 |

0Cr17Ni 12Mo2 |

≤0.08 |

16.00- 18.50 |

10.00- 14.00 |

≤2.00 | ≤0.035 | ≤0.03 |

2.00- 3.00 |

≤1.00 | - | - | - |

|

1Cr18Ni 12Mo2Ti6) |

≤0.12 |

16.00- 19.00 |

10.00- 14.00 |

≤2.00 | ≤0.035 | ≤0.03 |

1.80- 2.50 |

≤1.00 | - | - |

Ti5 (C%-0.02)~ 0.08 |

|

|

0Cr18Ni 12Mo2Ti |

≤0.08 |

16.00- 19.00 |

10.00- 14.00 |

≤2.00 | ≤0.035 | ≤0.03 |

1.80- 2.50 |

≤1.00 | - | - |

Ti5*C%- 0.70 |

|

| 316L |

00Cr17Ni 14Mo2 |

≤0.03 |

16.00- 18.00 |

12.00- 15.00 |

≤2.00 | ≤0.035 | ≤0.03 |

2.00- 3.00 |

≤1.00 | - | - | - |

| 316N |

0Cr17Ni 12Mo2N |

≤0.08 |

16.00- 18.00 |

10.00- 14.00 |

≤2.00 | ≤0.035 | ≤0.03 |

2.00- 3.00 |

≤1.00 | - | - | - |

| 316N |

00Cr17Ni 13Mo2N |

≤0.03 |

16.00- 18.50 |

10.50- 14.50 |

≤2.00 | ≤0.035 | ≤0.03 |

2.00- 3.00 |

≤1.00 | - | - | - |

| 316J1 |

0Cr18Ni 12Mo2Cu2 |

≤0.08 |

17.00- 19.00 |

10.50- 14.50 |

≤2.00 | ≤0.035 | ≤0.03 |

1.20- 2.75 |

≤1.00 |

1.00- 2.50 |

- | - |

| 316J1L |

00Cr18Ni 14Mo2Cu2 |

≤0.03 |

17.00- 19.00 |

12.00- 16.00 |

≤2.00 | ≤0.035 | ≤0.03 |

1.20- 2.75 |

≤1.00 |

1.00- 2.50 |

- | - |

| 317 |

0Cr19Ni 13Mo3 |

≤0.12 |

18.00- 20.00 |

11.00- 15.00 |

≤2.00 | ≤0.035 | ≤0.03 |

3.00- 4.00 |

≤1.00 | - | - | - |

| 317L |

00Cr19Ni 13Mo3 |

≤0.08 |

18.00- 20.00 |

11.00- 15.00 |

≤2.00 | ≤0.035 | ≤0.03 |

3.00- 4.00 |

≤1.00 | - | - | - |

|

1Cr18Ni 12Mo3Ti6) |

≤0.12 |

16.00- 19.00 |

11.00- 14.00 |

≤2.00 | ≤0.035 | ≤0.03 |

2.50- 3.50 |

≤1.00 | - | - |

Ti5 (C%-0.02)~ 0.08 |

|

|

0Cr18Ni 12Mo3Ti |

≤0.08 |

16.00- 19.00 |

11.00- 14.00 |

≤2.00 | ≤0.035 | ≤0.03 |

2.50- 3.50 |

≤1.00 | - | - |

Ti5*C%- 0.70 |

|

| 317J1 |

0Cr18Ni 16Mo5 |

≤0.04 |

16.00- 19.00 |

15.00- 17.00 |

≤2.00 | ≤0.035 | ≤0.03 |

4.00- 6.00 |

≤1.00 | - | - | - |

| 321 | 1Cr18Ni9Ti6) | ≤0.12 |

17.00- 19.00 |

8.00- 11.00 |

≤2.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | - | - |

Ti5 (C%-0.02)~ 0.08 |

| 0Cr18Ni10Ti | ≤0.08 |

17.00- 19.00 |

9.00- 12.00 |

≤2.00 | ≤0.035 | ≤0.03 | - | ≤1.00 | - | - | Ti≥5*C% | |

| 347 | 0Cr18Ni11Nb | ≤0.08 |

17.00- 19.00 |

9.00- 13.00 |

≤2.00 | ≤0.035 | ≤0.03 | - | ≤1.00 | - | - | Nb≥10*C% |

| XM7 | 0Cr18Ni9Cu3 | ≤0.08 |

17.00- 19.00 |

8.50- 10.50 |

≤2.00 | ≤0.035 | ≤0.03 | - | ≤1.00 |

3.00- 4.00 |

- | - |

| XM15J1 | 0Cr18Ni13Si4 | ≤0.08 |

15.00- 20.00 |

11.50- 15.00 |

≤2.00 | ≤0.035 | ≤0.03 | - |

3.00- 5.00 |

- | 2) | |